Our Strategic Tooling Partner Network

Custom Rubber Corp. works closely with three tool makers, all of whom specialize in making molds specifically for rubber. All of our strategic tooling partners are within 50 miles and all of them work very closely to jointly design new tooling. Partner with a specialist in tooling for rubber.

Tool making for rubber is a science and an art. Mold shops that claim to be "all-purpose" seldom have the expertise to provide the best solutions. Even companies that advertise expertise in both plastic and rubber often lack a depth of knowledge in either.

Together, the tool and die shops Custom Rubber Corp. works with have years of experience, all of which is available to our customers to insure the most robust and cost effective tool is built every time.

Trust the Experts

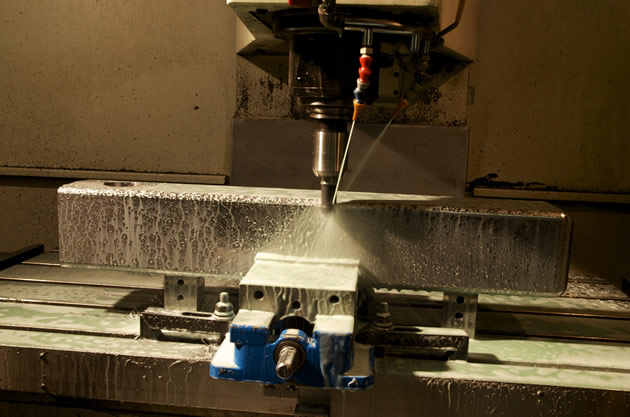

When you work with Custom Rubber Corp., your tools will be developed by our team in partnership with one of our dedicated tool makers. Custom Rubber Corp. and our partners all use SolidWorks (r) as our design software. Using a 3D design program allows us to insure cavities and part features are perfect before cutting any steel. It also allows us to simulate the mold cycle in order to anticipate opportunities for automation and address any potential concerns surrounding demolding.

All tooling we design is Made in the U.S.A. and Custom Rubber Corp. stands behind every single mold, guaranteeing its performance.

Proactive design for better solutions:

- Could a design change make manufacturing your part more efficient?

- Can an adjustment save you time and money?

- Will a slight modification make the molding process faster and better?

Years of tool design experience and multiple strategic partnerships can help to proactively optimize your tool design. Custom Rubber Corp. brings that experience to our customers.