There are some interesting ideas in a recent Wall Street Journal section entitled; Journal Report | The Future of Manufacturing published June 8, 2016.

Bob Tita's article talks about 9 different ideas out there to create a more level playing field for manufacturers and incentivise more R&D and advancement. Custom Rubber Corp. is continuing to grow, despite some of the barriers that exist, by partnering with customers that recognize the value of sourcing manufactured product in the U.S.

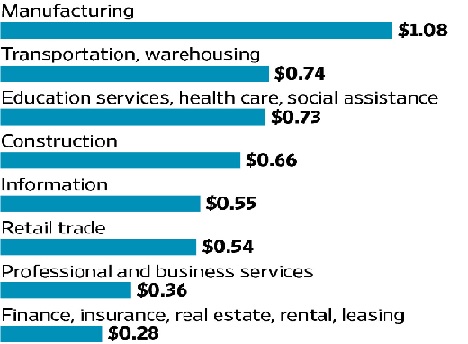

As Tita points out in his article, manufacturing leads all other industries in terms of generating additional transactions and economic benefit. The graph here says it all (Dollars of additional transactions generated by every dollar of value added in these industries) ...

Sources: Daniel Meckstroth, MAPI Fopundation; US Bureau of Economic Analysis

Without manufacturing, economies are doomed. According to Tita, "Countries that don't make anything eventaully start to lose their edge in research and product development." Steven Schmid added, "If you lose one, you'll lose the other, too." Custom Rubber Corp. is in the thick of manufacturing and research into improving productivity and product effectiveness.

One of the nine ideas to reviatlize US Manufacturing presented has to do with looking at the true costs of offshoring. I've written about this before when digging into the US Governments "Assess Costs Everywhere" project that outlines all the hidden costs associated with long, overseas supply chains. Tita's article highlights the fact that these do exist and that in some ways they are becoming more significant.

I also liked the ideas of "Spend More on Manufacturing R&D" and "Creating Regional Centers of Expertise."

Custom Rubber Corp. constantly pushes the envelope of what we manufacture within the rubber industry - investing in inernal R&D daily. We recently were successful in trialing and producing components that had three different materials combined in a part less than 1" x 0.25" x 0.25". One of the materials is a translucent silicone material. We are also investing reguarly in R&D - trying new materials for our customers that may lead to lower costs or better peformance.

Lastly, being located in Cleveland gives Custom Rubber Corp. access to expertise in just about every manufacturing process there is. Cleveland's rich history with manufacturing makes it easy to find suppliers to cast lead, do industrial sewing, supply specialty plastic inserts, and whatever else our customers need us to do. This allows us to be more for our customers than a shoot-and-ship molder of rubber products.