The ability to 3D print rubber is so new, it wasn’t even possible until a few years ago. It’s come a long way over the past three years, but it can definitely be argued that 3D printing rubber is a trend in itself.

The rubber industry has found so much use in 3D printing, however, that it’s a trend we expect to stick around for a long while. As technology advances and manufacturers unearth new applications, here’s what we can expect to see next in the world of rubber 3D printing.

For more information: Is is Possible to 3D Print Rubber?

1. The Continued Advancement of Materials

This is perhaps the biggest trend we can expect to see sooner than later. The rubber industry is already experiencing huge growth in available materials for 3D printing, Custom Rubber Corp. included.

When rubber 3D printing hit the scene, materials were limited as you cannot 3D print on any type of printer with natural rubber, EPDM rubber or any rubber material that doesn’t liquify, negating some of the most common rubber materials.

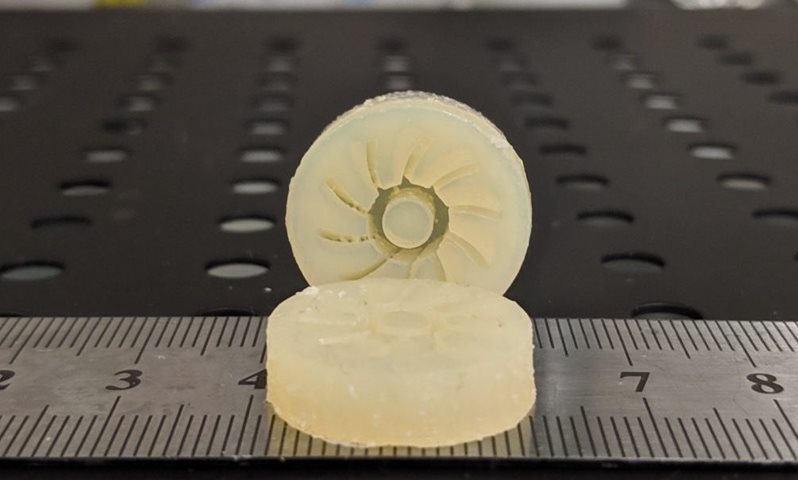

Suppliers started by working within the limited categories of urethane and silicone polymers. Many original rubber 3D printed parts had a foam-like texture that teared easily and offered little stretch.

Companies worldwide have since invested R&D dollars into developing new and innovative materials for 3D rubber printing. Dow Chemical launched two new silicone elastomers in 2019 intended for 3D printing, then partnered with two other companies to develop silicone elastomers allowing users to print in color.

In 2020, a team at Virginia Tech developed a method of 3D printing latex rubber via a new chemical compound. Latex is the liquid form of natural rubber. While it melts easily, it doesn’t harden without vulcanization. This new technique, developed by both chemical and mechanical engineers, hardens the material through UV exposure during application.

At Custom Rubber Corp., we have also expanded our range of materials offered for 3D printing applications. Two materials that are particularly popular are:

CRC RP 70 is our more popular option as it offers a larger print bed, meaning we can produce more parts per run. But both materials make it easier than ever before to print small production runs of 250 parts or less or create individual prototype parts with great success.

2. Bigger print beds with more parts and faster printing

The rubber industry spans the globe, with suppliers located primarily in South America and Asia and molding and production companies located in North America and Europe. The high number of companies with a vested interest in the advancement of rubber-related technologies allows for excellent collaboration and global innovation.

Right now, 3D print beds are still measured in millimeters. The average bed size as of writing is around 150-300 mm with larger models measuring in at 350-500 mm. There are a few of these large-scale models available on the market right now with competition growing steadily.

Print beds aren’t yet large enough for printing items like tires, but car and bike manufacturers are already incorporating smaller 3D-printed parts into new models. Tires may not be that far off!

Printers are also evolving to work faster and with more efficiency. In January 2022, Kwang-Min Lee, Vice President of Carima, a 3D printer manufacturing company, said the company’s new printers would be fast enough to complete “several tens of centimeters per hour.” That may not sound like a lot, but when print beds are only 30 centimeters at their largest, that’s a fully printed part finished in less than an hour.

3. 3D printing steel rubber molds

3D printing is advancing, but it’s not on track to ever fully replace traditional rubber molding methods. It’s unlikely 3D printing will ever be more efficient or less expensive than a mold when it comes to producing a high volume of parts.

Source - MoldMaking Technology

Source - MoldMaking Technology

That being said, rubber molds do have the disadvantage of traditionally being cast from steel. For typical prototype pieces or small-volume production, manufacturers have, in the past, had to first develop a steel mold before creating any parts. The process of creating the mold from a block of steel can be costly and time consuming.

3D printing steel molds would save manufacturers money, especially in cases of small volume or individual prototype production when these parts cannot be 3D printed. It is possible to 3D print metal, but the technology is still in its infancy. We estimate that 3D printed metal could become a faster and cheaper alternative to traditional metal casting in the next 2-10 years.

4. The ubiquity of low run, highly customized consumer products

Right now, 3D printed rubber is used most often for B2B products like gaskets, seals, connectors, medical equipment, hoses, plugs and many more small pieces. However, many B2C manufacturers have started to tap into its potential for consumer goods.

Many consumer products are made from silicone, an ideal material for 3D printing. Items like electronics cases are perfect for 3D print beds, as are glasses, shoes and soles, automotive interior parts and other small consumer goods.

3D printers allow for limited runs at a low cost. Manufacturers of consumer goods have plenty of opportunities for marketing special edition limited product releases or customizing goods to individual consumers. This technology is also useful for the medical and athletic fields when products must be customized to individual users.

It’s simple to take a design file and print anywhere from one to 250 parts rather than creating a traditional steel mold. The world of limited release rubber products and customized consumer goods is rife with opportunity.

To be clear, we don’t anticipate 3D printed rubber will ever become the industry norm. It’s not realistic or cost effective to 3D print thousands of parts at once. But don’t be surprised if 3D printing becomes the norm for small batch products and prototypes in the next decade as 3D printers and materials technology evolve.

Click here to get a quote on 3D printed rubber parts from Custom Rubber Corp. We’ll let you know the best options for your budget and application.